OKK VMC

Performed X-Axis ball screw service for an OKK MCV-1260 Vertical Machine Center. Nidec OKK had been making machine tools for 100 years in Osaka, Japan. OKK manufactured this vertical machining center. It also produced a horizontal machining center, a grinding center, a 5-axis vertical machining center, a 5-axis horizontal machining center, and a milling machine. The ball screw was removed from the machine for refurbishment. In addition to repairing the ball screw itself, which was damaged, the end bearings were replaced.

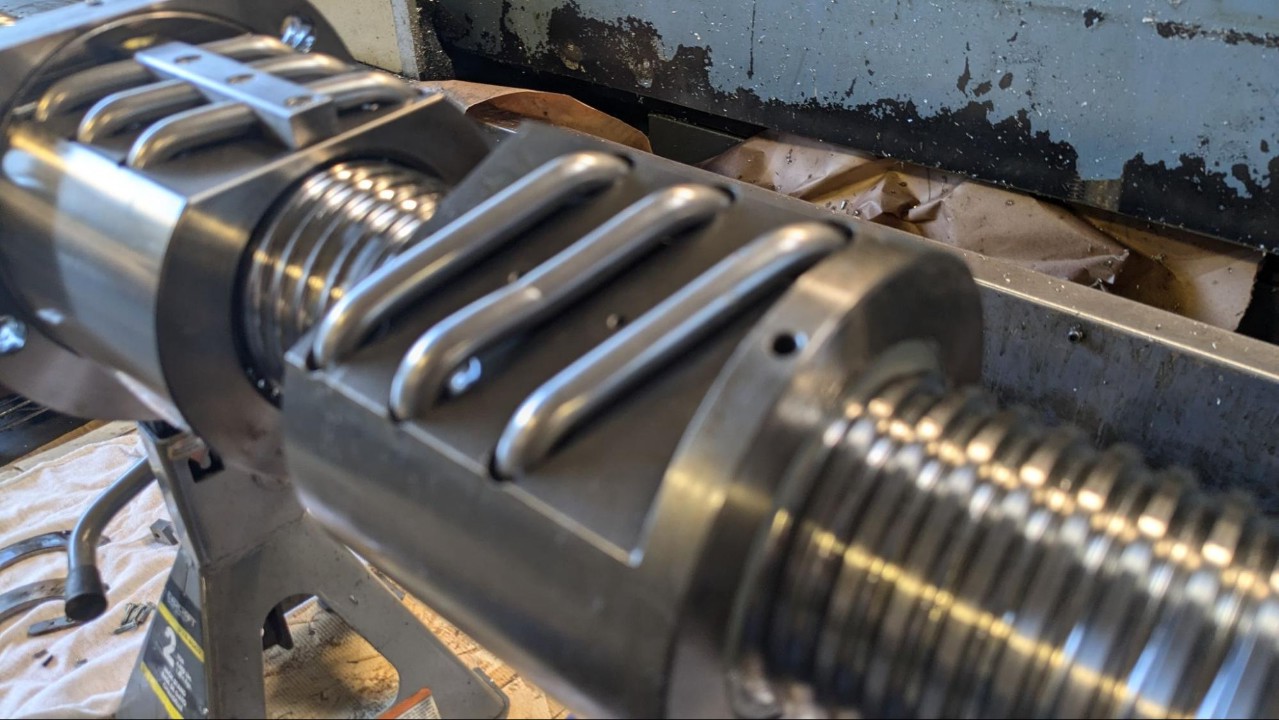

Here, the ball nut disassembly started. The preliminary cleaning was completed. This ball screw assembly locked up due to contamination in the ball nut mixed with lubrication failure. A new ball screw was available but was considerably expensive with a 9-month lead time, having to be shipped from Japan. This particular ball nut referred to as a split-nut. There were two ball nut halves with a spacer shim locked in between the two halves. This shim, with properly sized ball bearings, established the drag torque and preload of the ball screw assembly.

This is the root of why the X-Axis ball screw on the OKKK MCV-1260 ball screw failed. Lack of lubrication mixed with internal contamination caused one of the ball bearing return tubes to shear its ball scoop. The returns are the six metal tubes seen on the side of the ball nut. The ball bearings circulate around the ball screw shaft in a spiraled helix. Then they get pushed off the shaft into the return tube. Then they move back to the ball screw bearing track. Each one of these return tubes is a separate loop of balls. Notice that this failure happened on the back end or follower end of the split nut. This is because what little lubrication this assembly received was through the flange side of the split nut.

A close-up of the tube damage. This is a ball bearing return tube from the X-Axis ball screw found in an OKK MCV-1260 Vertical Machine Center. It was pushed out and bent after one of its ball bearing scoop “ears” sheared inside the ball nut. It pushed the side of the return tube up, deforming the tube before the screw locked up in the machine. The tube was straightened and reformed. Then, a new scoop was TIG welded onto the end of the ball bearing circulation guide tube.

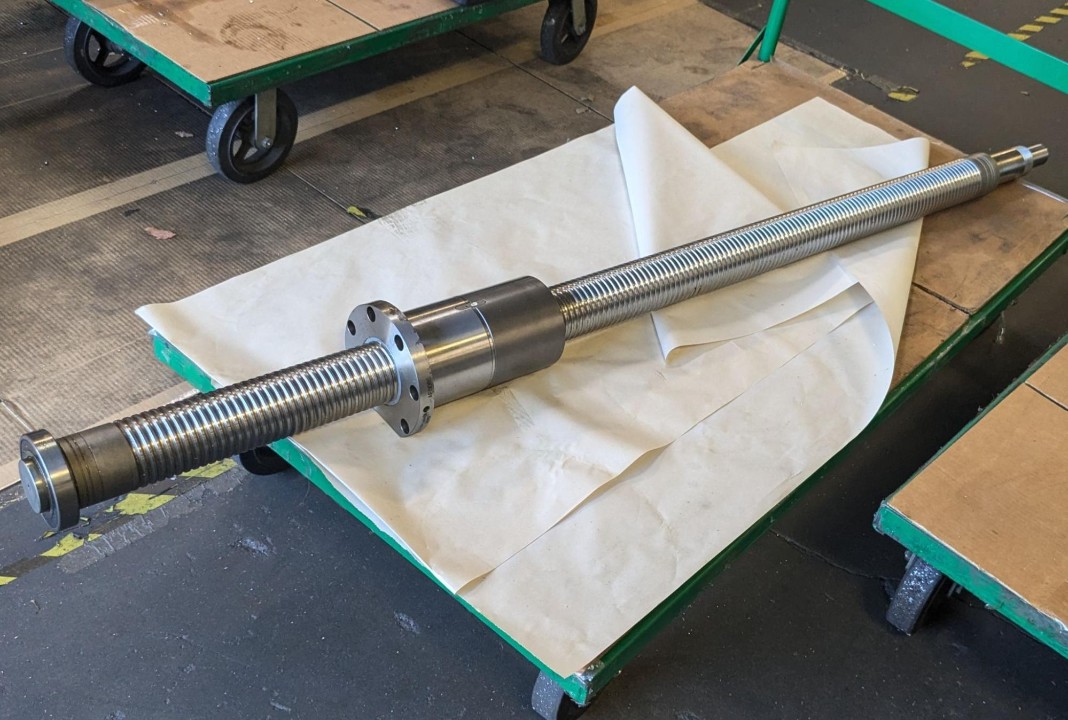

Ball screw after repairs and refurbishment. This was for an OKK MCV-1260 Vertical Machine Center. The X-Axis ball screw was cleaned up and polished by Ballscrew Guys techs. Drag torque and preload were returned to the assembly. Waiting for installation back into the machine.