Romeo Engineering Water Jet

In true Ballscrew Guys fashion, we are happy to help you get your older CNC machinery running. Sure, it has seen better days, but this Romeo Engineering waterjet still has a lot of life left. Here the X-Axis bridge ball screw is exposed. The covers have been removed. The cutting head has a slide-to-side clunk noise when you push on it by hand on either side. Signs of a seriously loose ball nut and ball screw assembly.

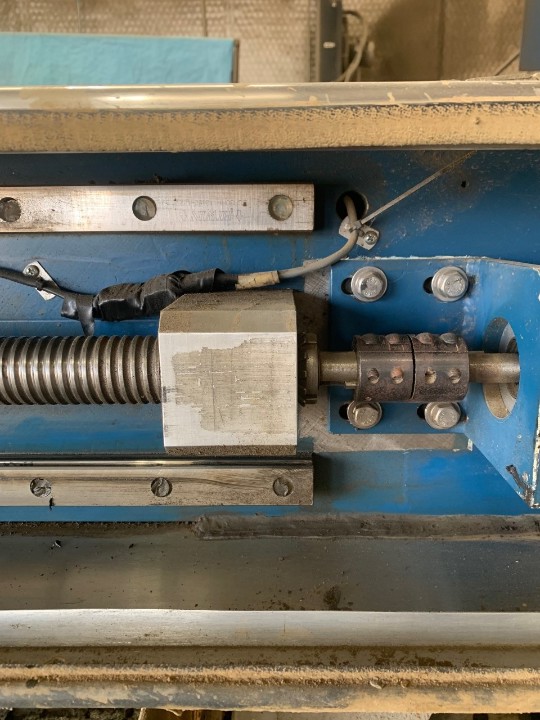

Image of the ball nut and ball screw behind the cutting head on a Romeo Engineering ball waterjet. This ball nut assembly is threaded into the cutting head yoke. The thread timing is different than ball screw shaft raceway helix. So getting the ball nut off the cutting head is a slight wrench-turning challenge.

The entire ball nut and cutting head yoke was disconnected to free the ball screw up from behind the cutting head. This ball screw assembly is the bridge-Axis ball screw on a Romeo Engineering ball waterjet. This design of ball nut is similar to the Western Digital and later Thompson adjustable twin nut styles, kind often seen on the backgauges for Cincinnati Press Brakes. The difference is the shaft and ball nut diameter. This is pretty stout. But even with the adjustable preload system, it will reach the end of its drag torque resistance when the ball bearings inside wear out.

Motor side end bearing housing as found on a Romeo Engineering waterjet. This bridge ball screw assembly has a basic coupling which connects it to the drive servo. This particular machine X-Axis had a gravelly, cement mixer noise in rapid traverse. The end bearings are worn out, like the ball nut. New end bearings were acquired and installed. The ball nut rebuilt. The machine X-Axis was quiet again. Positioning properly.